MOM solution brings everything together

Interview with Felix Losch, Dürr, and Martin Heinz, iTAC, about their joint development of the new Manufacturing Operations Management system

To enhance manufacturing processes and meet diverse customer requirements, seamless integration of digital technologies is necessary. Dürr partnered with its daughter company, iTAC, to develop a modular end-to-end solution, known as Manufacturing Operations Management (MOM). This integrated system aims to improve manufacturing process performance. Felix Losch, Senior Manager Sales Digital Products at Dürr, and Martin Heinz, Board member of iTAC Software AG, sat down with us to explain the advantages of MOM.

Martin and Felix, we have heard MOM being described as innovative and unique in the market. How does it differ from existing solutions?

Martin: Our end-to-end solution has a unique feature that no other software manufacturer is offering at the moment – a MOM platform capable of encompassing all digital factory functionalities within a standardized architecture. Unlike conventional solutions, our MOM platform boasts a universal user interface, communication standards, and a sophisticated user management system.

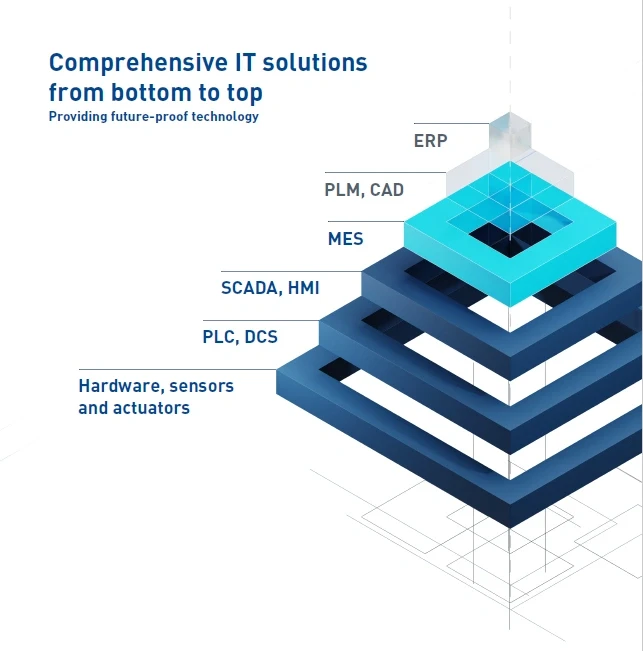

Felix: With many years of software experience, we noticed significant challenges faced by our customers. Issues such as high degrees of individualization, redundancies across various systems, and limited open software interfaces were becoming insurmountable barriers. Through our microservices architecture, our customers no longer encounter these barriers. MOM creates a uniform platform, instead of isolated solutions. At the control level, Supervisory Control and Data Acquisition (SCADA) acquires and analyzes the data, while at the higher command level, the production is controlled and monitored by the Manufacturing Execution System (MES) solution. This not only offers functional advantages but also reduces the investment costs.

Can you talk about the main reasons for the cooperation between Dürr and iTAC in advancing of the software further?

Martin: Through the cooperation, we are able to pool experience from different subject areas enabling us to not only leverage synergies and economies of scale, but also gain a technological advantage. The new MOM platform combines SCADA and MES functionalities, providing our customers with a seamless solution that merges these essential priorities. This solution was only made possible by the cooperation between the two teams. You could say it’s a win-win situation for Dürr and iTAC. With MOM, we can now offer our customers a one-stop shop for an integrated software solution as well as services.

Felix: iTAC’s process-oriented MES complements Dürr’s system-oriented SCADA solution perfectly. Our customers benefit from our collective experience in embedding such systems across different industries and application scenarios. The integrated concept avoids the need for interfaces, whether in the software or in the project teams themselves. These interfaces often entail the greatest risks during implementation.

What problems and challenges in the manufacturing industry does MOM address?

Martin: MOM targets the complexities in modern manufacturing processes by ensuring that all requirements are fulfilled and optimized on the fly if necessary. Since the system monitors and controls production in real time, MOM minimizes fault sources, avoids downtimes, and ensures traceability of all process steps, thus meeting compliance requirements. And tackling current industry challenges effectively.

Felix: Microservices offer a significant advantage as they can be installed on IIoT platforms in the cloud as well as on-premises, on-edge, or in hybrid scenarios in the factory. This gives the customer maximum flexibility when dealing with constantly changing requirements. For example, companies can integrate custom use cases into MOM or incorporate popular IIoT platforms. Large data volumes in the terabyte range can be processed on-edge which saves time, costs, and energy, providing the speed required for real-time control manufacturing processes.

Flexibility is an important feature of MOM. How do you achieve it?

Felix: While previous MES solutions were monolithic, in other words rigid and inflexible, MOM is modular. Numerous microservices operate and communicate with each other and fulfill their tasks completely independent of each other. Unlike monolithic solutions, microservices use autonomous data storage and open interfaces for communication with other services. Only functionalities that are actually needed are installed. This approach provides maximum flexibility to customers, including integration of application-specific proprietary developments.

The topic of cybersecurity is playing an increasingly important role in manufacturing. How secure is MOM?

Heinz: We have in fact seen a dramatic increase in attacks on operational technology systems – in other words hardware and software that control industrial equipment – in the past two years. For that reason, the focus must be on security requirements alongside specialist and technological aspects. The planned Cyber Resilience Act will establish what manufacturers need to consider in terms of cybersecurity. MOM is designed to meet future cybersecurity standards ensuring the highest level of IT security and long-term investment protection for our customers.

Losch: In our digital factory, we establish a hub that combines processes and guidelines for IT security in the company including the use of open source. We hold ISO/IEC 27001 certification, anchoring IT security as a core mission guarenteeing data integrity. MOM incorporates the UIAM platform service , which enables the assignment of users to corresponding rights and roles and implements security concepts for the communication between machines and other areas. Additionally, we work closely with our customers during software use, and maintenance contracts ensure that the most up-to-date security patches are always rolled out.

It took years to develop MOM. What feedback did you receive from the industry during this time, and how did it influence the further development?

Martin: Throughout the development phase, we presented the MOM platform to important customers, allowing us to incorporate their expectations into ongoing development. Just as important was the feedback from neutral organizations like the renowned Gartner management consulting company, which assesses MES/MOM providers in terms of their products and their performance with the Gartner® Magic Quadrant™. This feedback assured us that our MOM meets future market requirements and outpaces competitors. Similarly, insights from trade conferences and fairs reaffirmed this conclusion.